Bosch Esi Tronic 2.0 Free Of Charge

More than 30,000 electric schemes for more than 900,000 auto models and configurations.2. Technical manuals - SIS sector. More than 16,000 troubleshootingand repair instructions for 347,000 autos.3. The great bulk of the information is submitted on machines since 1971, but something is and on earlier samples. Bosch ESI 2.0 (A1, B1, B2) Spare parts catalog, Service Information, DiagnosticType: Spare parts catalog, Service Information, DiagnosticLanguages: English, Spanish, Italian, Mexican, German, Russian, Turkish, French, Swedish etc.Original spare parts catalog Bosch ESItronic represents the extensive catalogue of all production of firm Robert Bosch GmbH.The spare parts catalog and repair manuals Bosch ESI tronic supports all languages including Russian, has the good interface, allows to search under number of detail Bosch or any other manufacturer, gives out the information on application concrete spare parts on marks and models.The Program BOSCH Esi tronic supports all languages including Russian, has the good interface, allows to search under number of detail Bosch or any other manufacturer, gives out the information on application concrete spare parts on marks and models. Our partner Bosch has already eliminated more than 100,0000 autofaults by means of the proven solutions of the Bosch ESI 2.0 Online software.If you have still used SIS, EBR and P sectors in Bosch ESI 2.0 Online, they are available absolutely free of charge until.

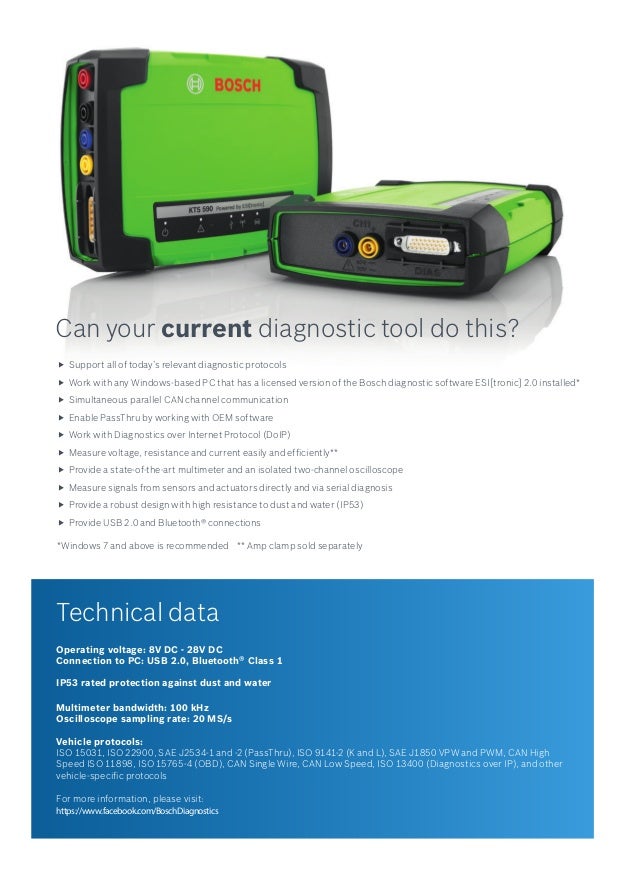

Because of the vast range of features available through the software, Bosch’s technical team will be breaking things down into bite-sized chunks, starting at a beginner level and progressing through to more advanced functions.In the first instalment of the series we covered the importance of selecting the right vehicle within Bosch ESI 2.0 to ensure that you get reliable information from the tool to assist with an accurate diagnosis and repair. KTS diagnotics made ‘ESI’ from Robert Bosch.This regular series of technical articles from Bosch focusses on how to get the best out of its ESI 2.0 software, which is used in conjunction with the KTS range of diagnostic tools for vehicle fault diagnosis and service function procedures. Over 10,000,000 approved solutions for specified auto faults.Auto service, based on EBR's experience, provides fast and simple maintenance for specified faults, obtained from the practice of car service centers. In addition to trusted sources such as Hotline service, Bosch applies a special algorithm that searches the forums for relevant errors and faults. This algorithm was specially developed by Bosch for EBR.

Then, if the ‘F5’ fault details button is clicked, a specific list of DTC’s and descriptions (where available) is then shown which again can be saved to the job protocol with the ‘Save’ F3 soft key. This can be very useful when analysing a vehicle before any in-depth diagnostic testing as certain faults – such as traction control and ESP problems – can log a DTC in more than one ECU (engine and ABS).The ‘F3’ save button can be used to store this complete list into the job report (‘Protocol’ – we’ll talk about this later). With some other cars the process may take a bit longer, as the KTS will have to check each ECU one by one for presence and fault status in each group.When the system overview is complete you will see a list of all ECU systems that are communicating and an indication if any fault codes are present. Certain vehicle brands can have up to 60 ECU’s that can all be checked in less than a minute, which makes it really quick for the technician to be able to assess the diagnostic state of the vehicle.

One of these features is an operation time stamp which could be useful if you’re justifying a lengthy repair process, or it can be turned off, if not needed.Under ‘Main menu’, ‘Protocols’ the list of stored reports can be accessed and, by clicking on ‘edit’ the customer details, job number, technician’s name and vehicle info can be added, along with any advisory comments to be reported to the customer.At any point the protocol file can be previewed and saved in. Other data includes the erase error memory function, actual value parameters in numerical format or time profile (this consists of a screen shot of the AV graphing) and also which actuators, function tests, adjustments/settings or special functions were performed.The amount of information that is saved in the protocol can be defined to suit your preference under ‘User settings’ in the main menu, along with your garage details that will appear on the report. This report will show the whole process followed by the technician during any diagnostic fault finding work.This could include a whole host of information, including the ECU system names and identification details, the number of trouble codes stored and descriptions, which trouble shooting (SIS) repair instructions have been followed and the results of any direct multimeter measurements made from the test plan. Whilst using the diagnostic features of the KTS, if you see the ‘Save’ or ‘Store’ (F2 or F4 soft keys) along the bottom, any data on the screen at that time will be added to the job protocol. ‘Protocols’ featureThis is another great feature in Bosch ESI 2.0. If the fault code is erased at this point, the overview list will refresh when you return to it, meaning that you can save a ‘before’ and ‘after’ status of the job that you’re working on to show to the customer.Using the protocol report (described in the next section), it is very simple to use the system overview to produce a professional and accurate vehicle report which can be used to justify any repairs that have been carried out in the workshop to the vehicle owner.

A new feature in ESI 2.0 is that you can now continue saving data to a previous protocol in the ‘last 30 vehicles’ list if you return to an unfinished job after working on other vehicles.We hope that these short explanations help you with these great Bosch ESI 2.0 features and if you’re not using them already, what are you waiting for?In last month’s column we covered System Overview and the excellent Protocol report features in Bosch ESI 2.0, which allow you to not only check the complete diagnostic state of a vehicle but also to produce a professional report of all the relevant functions and data to present to the customer. This is then added to the list in the main menu. The printed protocol report looks extremely smart (especially if printed in colour) and is great to attach to the invoice of a job that involved any diagnostic interaction so that the customer can see what was found and subsequently repaired (if necessary) to solve the problem.Every time a different vehicle is selected and some information is saved a new protocol report will be generated with the relevant details.

0 kommentar(er)

0 kommentar(er)